Whether you’re sprucing up your living space with custom furniture or adding a personal touch to your kitchen cabinets, CNC cutting from professionals like Lovech is your ticket to turning imagination into reality.

Understanding CNC Cutting

What is CNC Cutting?

CNC stands for Computer Numerical Control, but let’s keep it simple: think of it as the magical process where your design dreams meet precision cutting machinery. Unlike traditional manual methods, CNC cutting is all about automation, guided by digital designs to carve out intricate shapes with utmost accuracy.

How Does CNC Cutting Work?

- Design Phase – It all starts with a vision. You sketch out your design or whip it up digitally using software like AutoCAD or Adobe Illustrator.

- Digitalization – Once you’re satisfied with your design, it’s time to convert it into a digital format compatible with CNC machines. This step ensures that every curve and contour is translated flawlessly into machine-readable instructions.

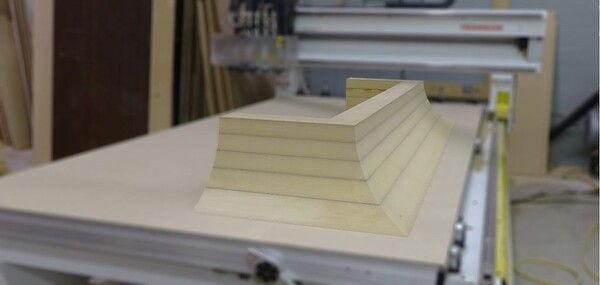

- Machine Setup – With your digital design in hand, it’s showtime! The CNC machine operator loads your design into the system, selects the appropriate cutting tools, and secures the material to be cut.

- Precision Cutting – The CNC machine springs to life, executing a series of meticulously calculated movements to carve out your design with surgical precision. It’s like watching a skilled artist at work, only this artist happens to be a high-tech cutting machine.

The Marriage of Art and Science

Precision Engineering Meets Creative Vision

One of the most beautiful aspects of CNC cutting is how it seamlessly blends the realms of engineering and artistry. On one hand, you have the cold, calculated precision of the machinery, ensuring every cut is exact to the micrometer. On the other hand, you have the boundless creativity of the human mind, shaping raw materials into expressions of beauty and functionality.

Pushing the Boundaries of Design

With CNC cutting, the only limit is your imagination. Intricate patterns, complex geometries, and unconventional shapes are all within reach, thanks to the precision and versatility of CNC technology. Whether you’re crafting custom furniture, decorative panels, or architectural elements, CNC cutting empowers you to push the boundaries of design like never before.

Ordering Custom CNC Cuts

Finding the Right Partner

So, you’ve got a killer design in mind, but how do you bring it to life? Enter CNC cutting service providers. These companies specialize in turning your design concepts into tangible creations, offering expertise, precision, and a keen eye for detail. But with so many options out there, how do you choose the right partner for your project?

Key Considerations When Choosing a CNC Cutting Service:

- Experience and Expertise – Look for providers with a proven track record in CNC cutting, with experience across a range of materials and design styles.

- Quality Assurance – Ensure the company maintains strict quality control standards, delivering cuts that are precise, clean, and free of defects.

- Customization Options – Every project is unique, so opt for a provider that offers flexibility in materials, finishes, and cutting techniques to bring your vision to life.

- Communication and Collaboration – Clear communication is key to a successful project. Choose a provider who values collaboration, keeping you in the loop every step of the way.

Bringing Your Vision to Life

The Consultation Process

Once you’ve found the perfect CNC cutting partner, it’s time to bring them into your creative vision. The consultation process is where the magic happens, as you collaborate with the experts to refine your design, select materials, and discuss any special requirements or considerations.

Iterative Design Refinement

Don’t be afraid to iterate! The beauty of CNC cutting is its flexibility, allowing you to tweak and refine your design until it’s absolutely perfect. Whether it’s adjusting dimensions, fine-tuning details, or exploring alternative materials, embrace the iterative process as an essential part of the creative journey.

Surfing the Waves of Change

3D Printing Integration

Picture this: CNC cutting and 3D printing joining forces to create a whole new dimension of design. It’s like the ultimate mashup, where textures come to life and forms take on a whole new level of complexity. Get ready to dive into a world where boundaries blur and imagination knows no limits.

Smart Manufacturing

Welcome to the era of smart manufacturing, where CNC machines are not just cutting, but thinking too. With sensors, AI smarts, and predictive analytics, they’re optimizing production like never before. It’s like having a super-smart assistant in the workshop, making sure everything runs like a well-oiled machine.

Sustainable Materials

The green revolution is in full swing, and CNC cutting is getting in on the action. From recycled plastics to bamboo composites, eco-friendly materials are taking center stage. It’s not just about cutting shapes anymore – it’s about cutting down on waste and leaving a lighter footprint on the planet.

On-Demand Production

Say goodbye to long lead times and hello to on-demand manufacturing. Thanks to platforms that connect creators with CNC cutting services, getting your designs made has never been easier. It’s like having a personal fabrication studio at your fingertips, ready to bring your ideas to life at the click of a button.

Embracing the Art and Science of CNC Cutting

So go ahead, dream big, and let CNC cutting bring your vision to life in stunning detail.